Revolutionize Process Development with Smart Mixing Strategies!

Optimize reactor performance, accelerate scale-up, and ensure consistent quality.

Modules

MixIT provides 3 modules which facilitates comprehensive stirred tank analysis using lab and plant data, empirical correlations and advanced 3D CFD models.

- Manage Geometry

- Operating Conditions

- Plant Measurements

- Experimental & CFD Data

- Design Reactors

- Compare Multiple Reactors

- Geometry Analysis

- CFD Analysis

- Simulation for Stirred Tank

- Tracer Simulator & Heat transfer

Let's Identify Your goals

Unlock the full potential of your innovative chemistry and formulations with optimal mixing. Efficient mixing ensures consistent product quality, maximizes reaction yields, and minimizes batch times. MixIT's data-driven approach empowers you to tackle common process development challenges and achieve breakthrough results.

Features Of MixIT

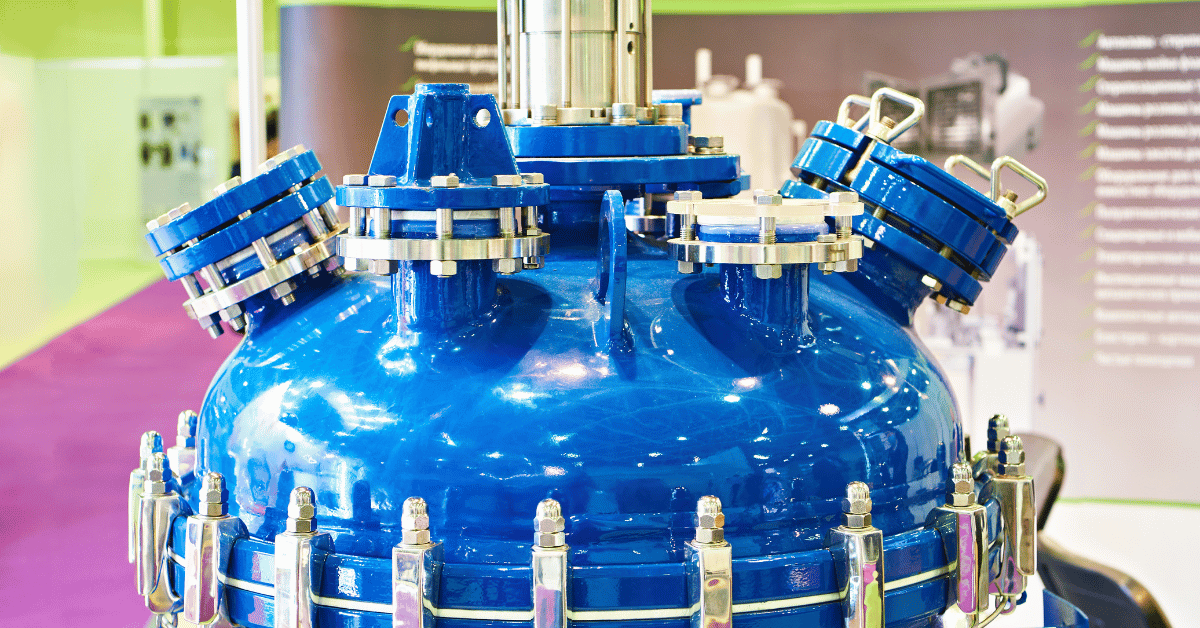

Reactor Configuration and Process Specification

MixIT streamlines reactor setup & recipe specification to capture your process details with ease

- Ease of configuring complex reactor setups, including multi-shaft agitator support

- Extensive library of impellers help create 3D tank models in matter of minutes

- Supports Round, Square, Rectangular and Horizontal tanks with top, bottom and side entry shafts

- Various bottom shapes – flat, conical, hemispherical, torispherical etc. are available

- Dip tubes, baffles, coils, inlets, outlets, spargers, jackets can be accomodated

- A wide class of rheology models support both Newtonian and non-Newtonian fluids

- Liquid formulations, Emulsions, Suspensions, Gas sparged systems can all be studied

- Custom impellers, baffles and other internals can be imported with just a click

Simulation and Analysis

MixIT provides comprehensive simulation and analysis features and functionality to optimize reactor performance.

- Use industry standard correlations to estimate various mixing parameters – MixIT predicts 26 mixing parameters that can help with process design, scale up and trouble shooting.

- Fully automated 3D CFD simulations enables chemists, biologists and process engineers to generate mixing analysis reports with ease.

- CFD analysis provides flow profiles, identifies dead spots, predicts blend times, solid and gas bubble distribution profiles, droplet size estimation etc. for an enhanced understanding of process

Visualization and Prediction

MixIT visualizes flow behavior and predicts outcomes for informed decision making

- Predict mixing performance, including power draw, blend times, mixing intensities, mass transfer coefficients, heat transfer rates, vortex shapes

- Visualize concentration gradients, solids or gas bubble distribution in the reactor, enhancing process comprehension

- Create power visuals and animations that enable your enterprise to easily comprehend mixing issues and resolve them fast

Reference Customers

Use Cases

Unlock the power of process optimization! Dive into our use-case library to explore real-world examples of how companies across industries leverage our solutions. Discover how we've worked on challenges like yours and empowered our customers to achieve their goals.

MixIT Advantageous

Boost productivity with MixIT's customization and flexible deployment.

Tailor performance analysis to meet specific needs. Create custom correlations that accurately reflect the unique behavior of reaction system for enhanced process modeling.

Gain real-time insights into your simulations. Track key parameters like turbulence models and species concentration as simulation progresses, allowing for immediate adjustments and optimization.

Input quantities in various units and seamlessly switch between systems as needed, ensuring a smooth workflow regardless of data format.

Optimize mixing with precise vortex control. Predict the shape and depth of impeller vortices for different operating conditions. This allows to fine-tune your mixing strategy for optimal results.

Simulate any mixing scenario with the access a comprehensive library of built-in impellers and import custom options for accurate simulations regardless of reactor configuration.

MixIT's delivers precise simulations, accelerating your optimization process and saving you valuable time. Resulting in faster and accurate results.

Monitor your simulations in real-time within a user-friendly interface, allowing for efficient design adjustments and informed decision-making.

MixIT handles both mixing and heat transfer using simulations, providing a holistic view of process for optimal design and control.

Choose the deployment option that best the requirements. Implement MixIT on own server for complete control or leverage the convenience of a public cloud solution.

%20(1)-1.jpg?width=300&height=300&name=Damo%20(1)%20(1)-1.jpg)